一 管链输送机概述 Introduction

管式输送机又称管式链板输送机,工作时,装有圆盘刮板的链条在封闭的管路中运动,依靠刮板推动物料沿管路向前输送,是一种节能、连续输送设备。

Pipe conveyor is also called the tube chain conveyor, work, equipped with disc scraper chain movement in the closed pipeline, rely on the scraper push forward along the pipeline conveying materials, and is a highly efficient, energy saving, continuous conveying equipment.

二、管链输送机工作原理working principle

管链输送机是输送粉状、小颗粒状及小块状等散状物料的连续输送设备,可以水平、倾斜和垂直组合输送。在密闭管道内,以链片为传动构件带动物料沿管道运动。当水平输送时,物料颗粒受到链片在运动方向的推力。当料层间的内摩擦力大于物料与管壁的外摩擦力时,物料就随链片向前运动,形成稳定的料 流;当垂直输送时,管内物料颗粒受链片向上推力,因为下部给料阻止上部物料下滑,产生了横向侧压力,所以增强了物料的内摩擦力,当物料间的内摩擦力大于物料与管内壁外摩擦力及物料自重时,物料就随链片向上输送,形成连续料流。

tube chain conveyor is a continuous conveying equipment conveying powder, small granular and small bulk materials, which can be transported horizontally, slanted and vertically. In the closed pipe, the chain plate is used to drive the material along the pipe. When horizontal transport, the material particles are driven by the chain in the direction of motion. When the internal friction force between the material layer is greater than the external friction of the material and the pipe wall, the material will move forward with the chain plate to form a stable material flow. When vertical conveying pipe material particles by chain upward thrust, because of the lower to the upper material to prevent slipping, the transverse lateral pressure, so to enhance the material internal friction, when the friction between the material is greater than the material and pipe wall friction and material weight, the material is with chain upward transportation, form continuous material flow.

三、翼虎管链输送机优势advantage:

1. 结构紧凑,占用空间小,可以三维改变输送方向,不受地形、角度与高度的影响;输送过程在密闭的管路中进行,物料无污染,无粉尘飞扬;

2. 输送过程平滑,物料间基本无内部内部运动,破损少,保证物料品质,适合磨蚀性物料;

3. 不会产生系统堵塞,适合输送多种形态的物料;

4. 对混合物料的输送,不会产生物料分层现象

5. 输送能力大,能耗低,大降低设备运行成本

6. 所有运动部件全部在密闭的空间内运行,安全、可靠

7. 可实现远距离输送

8. 可随意部署多个进出料口,满足工艺要求

9. 易于实现集中控制,提高自动化程度

1. Compact structure, small footprint, can change the direction of transportation in three dimensions, without the influence of topography, Angle and height; The conveying process is carried out in the closed pipeline, the material is free from pollution and the dust is free.

2. Smooth transportation process. There is little internal internal movement between materials, so that there is little damage, and the material quality is guaranteed to be suitable for abrasive materials.

3. There will be no system clogging, suitable for conveying various types of materials;

4. The transport of mixed materials will not produce material stratification.

5. Large transportation capacity, low energy consumption, large reduction of equipment operation cost.

6. All moving parts are operated in confined Spaces, safe and reliable.

7. Remote delivery can be achieved.

8. Multiple inlet and outlet can be deployed at will to meet the process requirements.

9. Easy to realize centralized control and improve the degree of automation.

四、 管链输送系统的应用领域Application:

1. 塑料工业:PVC、PP PE粉料,ABS PC PP PE 颗粒

2. 精细化工:染料 颜料 涂料 碳黑 钛色素 氧化铁 陶粉 重质碳酸钙 细颗粒碳酸钙 皂土 分子筛 瓷土 硅粉 活性炭

3. 矿业:尿素 氯化铵 碳酸氢铵 苏打粉 固态杀虫剂 钨粉 鱼油 铜矿粉 煤粉 块状磷酸盐 矾土等

4. 建筑材料:水泥 粘土 黄沙 石英沙 粘土粉 硅 石灰粉 白云石粉 木屑 玻璃丝 二氧化硅 画粉等

5. 食品工业:面粉 淀粉 谷类,奶粉 食物添加剂等

1. Plastics industry: PVC, PP PE powder, ABS PC PP PE particle.

2. Fine chemical industry: dye pigment coating, carbon black titanium pigment, iron oxide ceramic powder, heavy calcium carbonate, fine particle, calcium carbonate, calcium carbonate, silica, silica, activated carbon.

3. Mining: urea ammonium bicarbonate ammonium bicarbonate sodium bicarbonate, solid pesticide, tungsten powder, fish oil, copper powder, coal powder, lump phosphate, bauxite, etc.

4. Building materials: cement clay, yellow sand, sand, quartz, clay powder, silica powder, white dolomite, silk-glass, silica, silica, etc.

5. Food industry: flour starch grains, milk powder food additives, etc.

五、 管链输送机材质material:

管道、机壳、链条、链轮:采用SS-304不锈钢

链板:尼龙

其它部件采用碳钢,如需其他材质请说明

Piping, chassis, chain, sprocket: ss-304 stainless steel.

Link plate: nylon

Other parts are made of carbon steel. Please specify other materials.

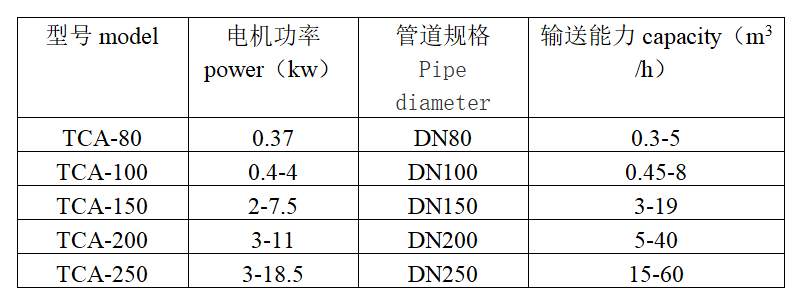

六 管链输送机参数parameter

七、布置形式