MS水平埋刮板输送机

MS scraper conveyor

产品介绍

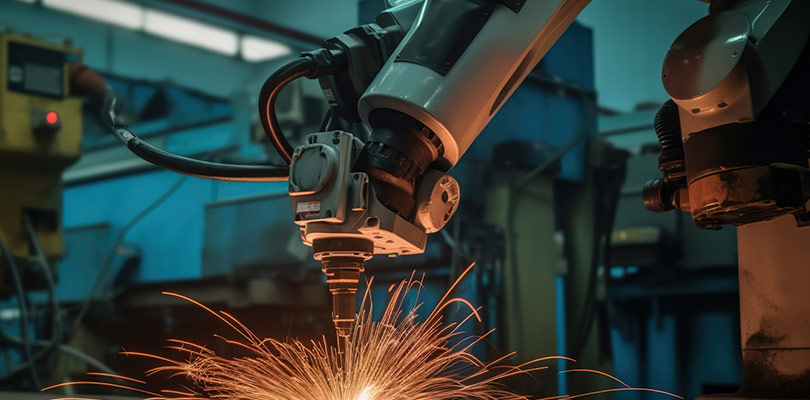

MS水平埋刮板输送机常用于输送小粒状和粉状物料,亦能在15°角范围内作倾斜输送,因此在单点进出料基础上也可多点进出料。对输送有毒、易爆、高温和易飞扬的物料,改善工人操作条件和减少环境污染等方面有独特长处。MS水平埋刮板输送机可分固定式和组合式两种,并可通过改变中间段数量来满足不同输送距离要求。该机广泛应用于料仓及粮油、饲料和散装物料,化工、水泥、冶金、建材、机械等行业和部门,是连续输送粉状、小颗粒状和小块物料理想的输送设备。

MS scraper conveyor is often used for conveying of small granular and powdered materials, also can be in 15 ° inclination conveying Angle range, so based on the single point of access to material can also be more in and out of the material. It has unique advantages in conveying toxic, explosive, high temperature and easily flying materials, improving working conditions of workers and reducing environmental pollution. MS scraper conveyor can be divided into two types, which can be divided into two types, and can meet the requirements of different conveying distances by changing the number of intermediate segments. This machine is widely applied in the bin and grain and oil, feed and bulk materials, chemical industry, cement, metallurgy, building materials, machinery and other industries and departments, is a continuous transporting materials in shape of powder, small grains and small pieces of the ideal transport equipment.

产品特点:

1、使用模锻链和套筒滚子链拖动刮板,具有负荷能力大,链条寿命长和强度高的特点。

2、链条能自动张紧,可保证链条在长时间内始终处于适度张紧状态下运行,省去人工必须及时而频繁的紧张操作。

3、链条和刮板回程段由托轮支承运行,不仅省力减磨,而且通过回链若干托轮间挠度的自动变化,有助于链条的自动涨紧及滑行。

4、如驱动机构背负在机头上部与机壳自成一体,可使整体安装不需用地脚螺栓即可就地自由放置而运行。

5、运行速度可采用YVP系列电机和变频器组合控制,是国际上**调速方式。

6、进料方式采用两侧大尺寸通过分流进入,使回程链条及刮板与进料隔离,并以不变的大尺寸料层厚度向前输送。使链条及刮板回带物料的现象不再发生。1. Use the die forging chain and sleeve roller chain to drag the scraper, which has the characteristics of large load capacity, long chain life and high strength.

2. The chain can be tensioned automatically, so that the chain can be operated in a moderately tight state for a long time, eliminating the need for timely and frequent nervous operation.

3. The return passage of the chain and scraper is operated by the supporting wheel, which not only reduces the friction, but also helps the chain to tighten and glide by automatic

工作原理:

MS水平埋刮板输送机主要由头轮、尾轮、输送链、机壳及驱动装置等组成。输送散料时,散料具有内摩擦力和侧压力等特性,物料受到刮板链条在运动方向的推力,当料层间的内摩擦力大于物料与槽壁间的外摩擦力时,物料就随着刮板链条向前运动,由于输送时刮板链条全被埋在物料之中,故称为埋刮板输送机